Materials

We process fluoropolymers and high temperature thermoplastics. Fluorothermoplastics are high-performance melt polymers consisting of tetrafluoroethylene and other fluorinated monomers. They are characterized by exceptional heat and chemical resistance, optimum weather resistance and excellent electrical properties. The following materials are part of our range of services:

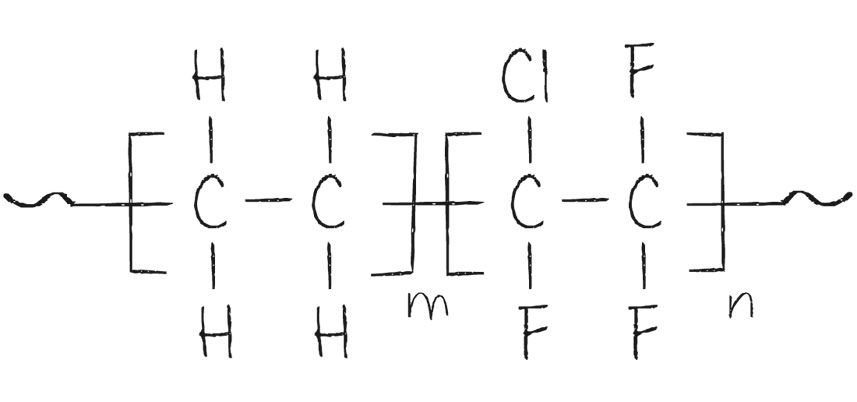

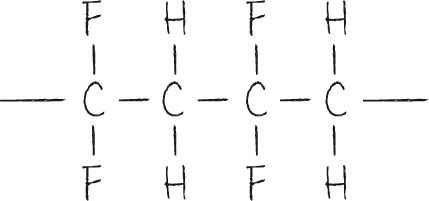

ECTFE

Ethylenechlorotrifluoroethylene (ECTFE) is a partially crystalline, thermoplastic fluorine- copolymer having good strength and hardness. Its property profile comes close to that of PVDF. ECTFE shows a lower permeability than PTFE on chemicals, why it is therefore particularly suitable for applications in chemical industry.

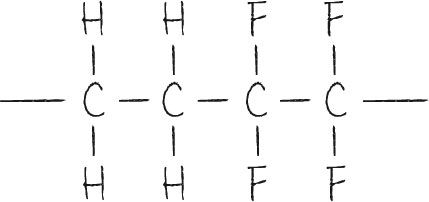

ETFE

Ethylenetetrafluoroethylene (ETFE) is a partially crystalline, thermoplastic copolymer of ethylene and tetrafluoroethylene (TFE). Like many other fluorine-copolymers, ETFE was developed in order to improve the melt processability of PTFE. ETFE shows a continuous use temperature about 100°C lower than PTFE, while possessing improved mechanical properties and almost the same resistance to chemicals.The melting point of ETFE is about 255°C.

FEP

Polyfluoroethylenepropylene (FEP) is a copolymer of TFE and hexafluoride-propylene. In contrast to PTFE, FEP is thermoplastically processable due to its lower melting viscosity, offering though comparable properties upon contact with chemicals and as an electrical insulator. However, the mechanical properties of FEP and the temperature resistance are lower than those of PTFE. The melting point of FEP is about 255°C.

MFA

PAEK

Polyetheretherketone (PAEK) is a high temperature resistant thermoplastic material and belongs to the substance group of the polyaryletherketones. Its melting temperature is 335°C. PAEK is resistant to almost all organic and inorganic chemicals, and also to hydrolysis up to about 280°C. However, it is not resistant to UV radiation, concentrated nitric acid, generally acidic oxidizing conditions, and to some halogenated hydrocarbons and aliphatic hydrocarbons at higher temperatures. In concentrated sulfuric acid are completely dissolves already at room temperature.

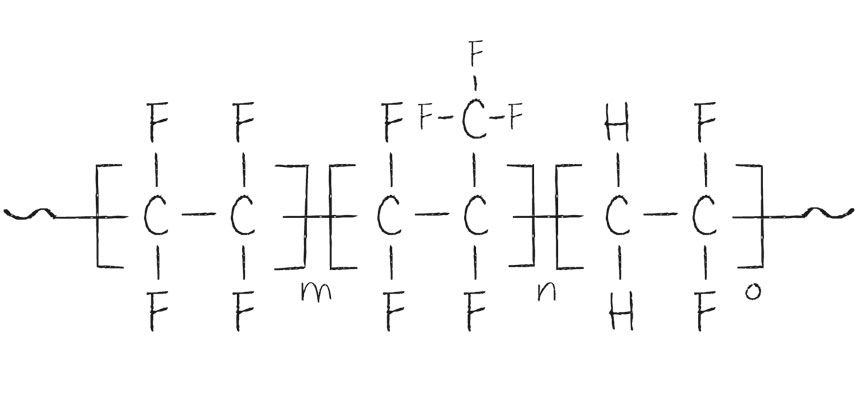

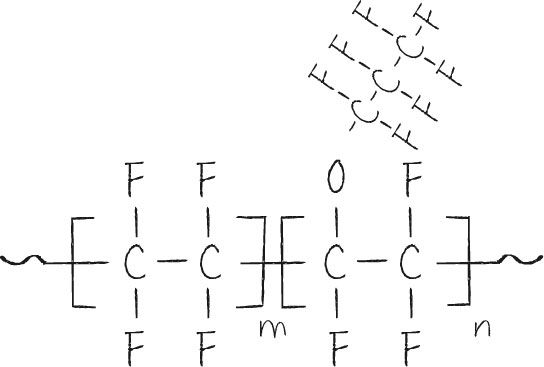

PFA

Perfluoroalkoxy (PFA) is a thermoplastic copolymer of perfluoride propylvinylether (PPVE) with tetrafluoroethylene. The proportion of PPVE is considerably higher in this polymer than it is in for example in modified PTFE. Additionally it has a lower molecular weight than conventional PTFE. The combination of both effects result in a completely thermoplastic-processable perfluoride polymer providing only slightly inferior properties as PTFE. The melting point of PFA is around 305°C.

PVDF

Polyvinylidene fluoride (PVDF) is a highly crystalline, thermoplastic fluoroplastic with relatively balanced mechanical properties. Compared to PTFE, PVDF has a significantly improved stiffness and compressive strength, but also a significantly lower permanent service temperature of up to 150°C. PVDF shows a high resistance to powerful radiation and is considered physiologically harmless. Moreover, this plastic meets the highest purity and therefore preferably used for applications in chemical, food, and semiconductor industries.

THV

THV is a terpolymer consisting of tetrafluoroethylene, hexafluoride propylene, and vinylidene fluoride. Its melting points are between 210°C and 265°C.